Get an alloy wheel refurb. Brand new looking alloys. Carbon dipping specialists Wicked Coatings specialise in refurbishing wheels. We are open for business as usual!

Any excessive damage, corrosion, buckling, or welding may incur additional charges. Next the wheels are gently heat treated to remove any air from the alloy and a first stage powder coat finish is applied and then cured for a set time period. After this if the wheel is having a “special” or “bespoke” finish the wet-in-wet procedure takes place (e.g. special paint and clear-coat finish). The wheels are also automatically subjected to a further thermal treatment.

What is alloy wheels powder coating? Where can I repair my alloy wheels? How much does alloy wheel repair cost? Acid Stripping and Powder Coating.

Some wheels are prone to rotting and corrosion and there are a number of ways to treat this. Some companies ‘shot blast’ or ‘sand blast’ wheels to remove all the paint and corrosion.

Speedy’s alloy wheel refurbishment service is available at all our branches. The stainless steel work basket which is supplied with the tank has a quick release collection tray which, with every alloy wheel batch, withdraws from the tank.

To empty the tray there is an easy to use release mechanism which ensures as little stripped paint is removed as possible. This has the added advantage of adding to operating efficiency by keeping the chemicals as clean as possible.

How to repair alloy wheels and refurbish them. A good set of alloy wheels can make a standout car—but only if they’re in tip-top condition.

It’s also pretty soft compared to the steel construction of a more basic and cheaper wheel. What that adds up to is, over time, your alloys will suffer corrosion, dents and dings will. Browse our extensive gallery below to see a huge selection of various 3D objects that have been carbon fibre dipped. Acid Dipping is used to remove the old paint from the alloy wheels surface when refurbishing them.

The acid is held in a bath, and the alloys are left to soak under the aci until the layers of paint have broken down and come away from the surface of the alloy wheel completely. CLEAN, KEYE PAINT-READY.

Our solutions provide the best paint-ready finish for 99% of wheels in as little as hours. Before Stripping An Aluminium alloy wheel, ready to be stripped. Alloy Wheel Stripping. During Stripping The paint is lifted off the s. Our full refurbishment involves stripping the wheel, then sandblasting to remove any corrosion, then any damage or lumps and bumps are removed or filled.

We then apply a protective undercoat, colour and the wheels are baked in the oven for a lasting finish. Splash Powder Coating is an alloy wheel refurbishing company. From paint stripping and welding cracks to custom powder coating design for your alloy wheels, we offer a full refurbishment and repair service to make your wheels look brand new again.

Ceramic coating for alloy wheels Ceramic coat is not a sealant or a wax, it’s a nano ceramic coating that forms a permanent adhesion to the paint and can only be removed through abrasion. When cure this unique and highly advanced formula will transform itself on the surface to a permanent rigid glass shield.

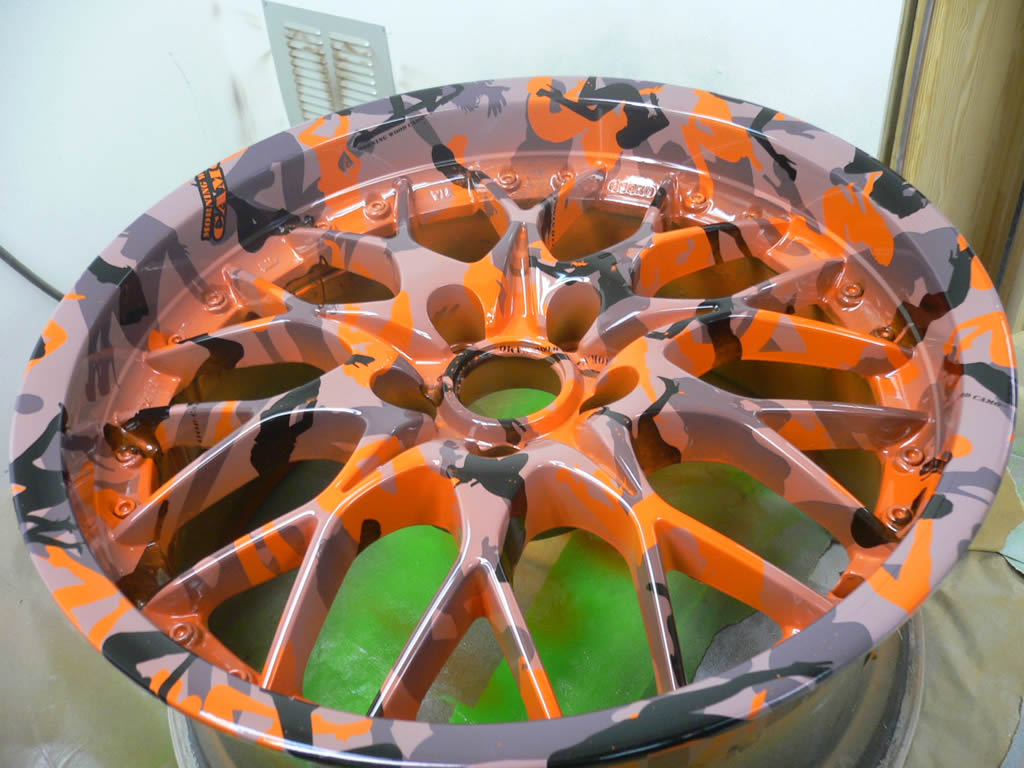

Based in Preston, we offer an excellent service throughout the entire North West. Vital Hydrographic specialist in high-end hydro dipping and carbon dipping solutions. Offering the very best in bespoke hydro dipping design, if it’s got a surface then most likely we can dip it.

At Vital we only employ the very best hydro dippers and paint sprayers in the industry, and our quality standards are next to none.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.